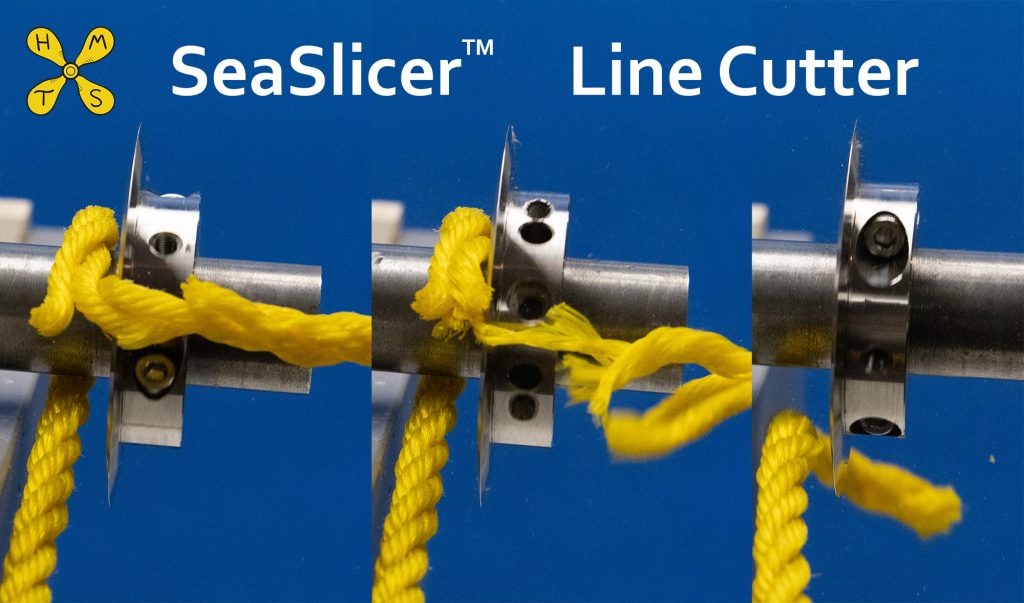

SeaSlicer™ has the easiest & safest install on the market. The split design with our patent-pending installation tool makes it easy to start cutting your way to safer sailing. SeaSlicer™ can cut through common materials you’ll find waiting to wrap around your propeller shaft. Check out a few examples of our tests that we’ve run with the SeaSlicer:

SeaSlicer™ Package & Install

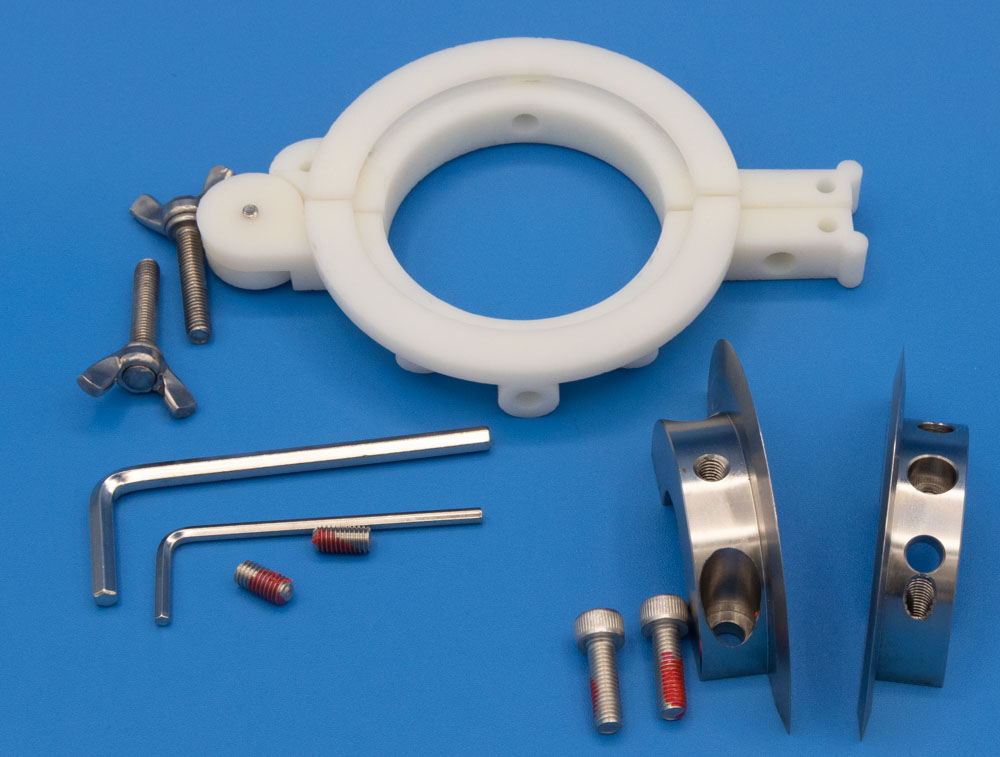

The SeaSlicer comes with the cutter itself, 316 stainless steel bolts with Vibra-Tite VC-3 pre-applied, 316 stainless steel set screws with Vibra-Tite VC-3 pre-applied (optional to use, provides more grip strength), hex drivers, and our patent-pending installation tool:

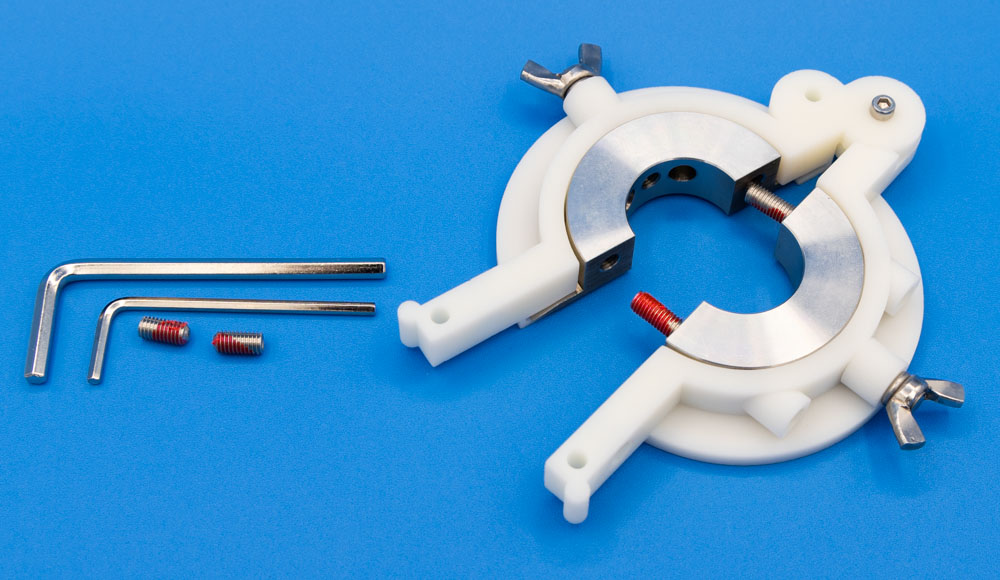

The install tool comes packaged with the cutter preinstalled, along with the socket screws held captive and ready for you to use.

Installing it requires you to just put over the propeller shaft & tighten the screws. The install tool keeps your hands safe from the sharp blade, prevents you from dropping and damaging the cutting tool, and holds the screws captive until they are securely locked in place. It’s so easy you can even install it underwater!

We include a lanyard hole as well, which you can use to attach the install tool to yourself, your tool box, or the propeller shaft depending on what stage of the install you’re at. Perfect when installing it underwater, or on a boat that is up on high tide and in a bit of muck. No risk of dropping it into whatever is below! Even if you’re on dry land, this prevents you from dropping the SeaSlicer and damaging the cutting edge.

3rd Party Line Cutter Tests: Disc Style vs. Others?

How well do line cutters work? You might have seen the many other types of line cutters and wonder if the simple & low-cost SeaSlicer works as well as the other types with fixed & moving blades, or serrated edges. You don’t need to believe us – Yachting Monthly had a comprehensive tests of different types. The results showed that all styles worked well – there are advantages & disadvantages of the different types. For example while the more complex styles with both fixed & moving blades can cut thicker rope, they can become jammed and require hauling the boat to repair. Our simple disc style has no maintenance & can easily be sharpened if required. We like simplicity in our products because there is already more than enough boat maintenance as is! But ultimately choosing to install any line cutter is a huge step forward, whatever style you choose. Check out the video here:

Ordering Information

Shaft Size?

We currently have the following standard sizes, but can create custom sizes as well. Minimum orders or engineering costs may apply to custom sizes, but often you won’t be our only request so your custom size might be a standard size we’re waiting to release! Much larger sizes are available, due to demand we list the most popular smaller sizes here.

All prices include our patent-pending installation tool, all required hardware, and basic installation tools (Allen keys). Proper installation suggests using a torque wrench to set the bolt torque to the exact value.

Our optimized manufacturing process gives us our lower cost without sacrificing quality. You’ll find similar sized split line cutters selling for double the cost!

| For Shaft Size | Cutter Width | Outside Diameter | Part Number | MSRP (CAD) |

|---|---|---|---|---|

| 1.0″ | 0.55″ (9/16″) | 3.0″ | HMSS-1.00IN | $375 |

| 1.125″ (1-1/8″) | 0.55″ (9/16″) | 3.0″ | HMSS-1.125IN | $375 |

| 1.25″ (1-1/4″) | 0.55″ (9/16″) | 3.0″ | HMSS-1.25IN | $375 |

| 25mm | 14mm (0.55″) | 76.2mm (3.0″) | HMSS-25MM | $375 |

| 30mm | 14mm (0.55″) | 76.2mm (3.0″) | HMSS-30MM | $375 |

NOTE: The cutter width is the width of the actual cutter block. Your cutlass bearing needs waterflow for cooling, at least 1/4″ is recommended, but this is not a binding recommendation. Your bearing may require more space, consult a marine engineer or other expert as there are different installations!

If you need to replace the installation tool (because you damaged or lost it for example, and plan on using the tool for protecting the SeaSlicer when the boat is being moved), it is available under part number HMSSTOOL-3.0IN . The same tool is used for the same outer diameter. Currently there is only the one tool available, and there are not tools for other suppliers cutters available.

Installation Instructions

You can see and download the full installation instructions below:

Batch Testing Results

Like all our metal products, SeaSlicer™ is subject to rigorous quality testing. Here is a list of batch reports, which you can match with the batch number on your SeaSlicer™ label:

Disclaimers

NOTE: Product may not be exactly as shown. We are continuously making improvements to our design and products, and this page may not reflect the latest version of our products. Examples of such changes may include but are not limited to adjusting the length of bolts, colors or composition of plastic parts, lengths and styles of included tools, and use of bolt locking mechanisms.

SeaSlicer is a trademark of Halifax Maritime Tool and Supply. The SeaSlicer installation tool has patents pending, and may be subject to patent enforcement worldwide.

VC-3 and Vibra-Tite are registered trademarks of ND Industries, Inc. Use of the VC-3 and Vibra-Tite trademark does does not imply endorsement from ND Industries, Inc.